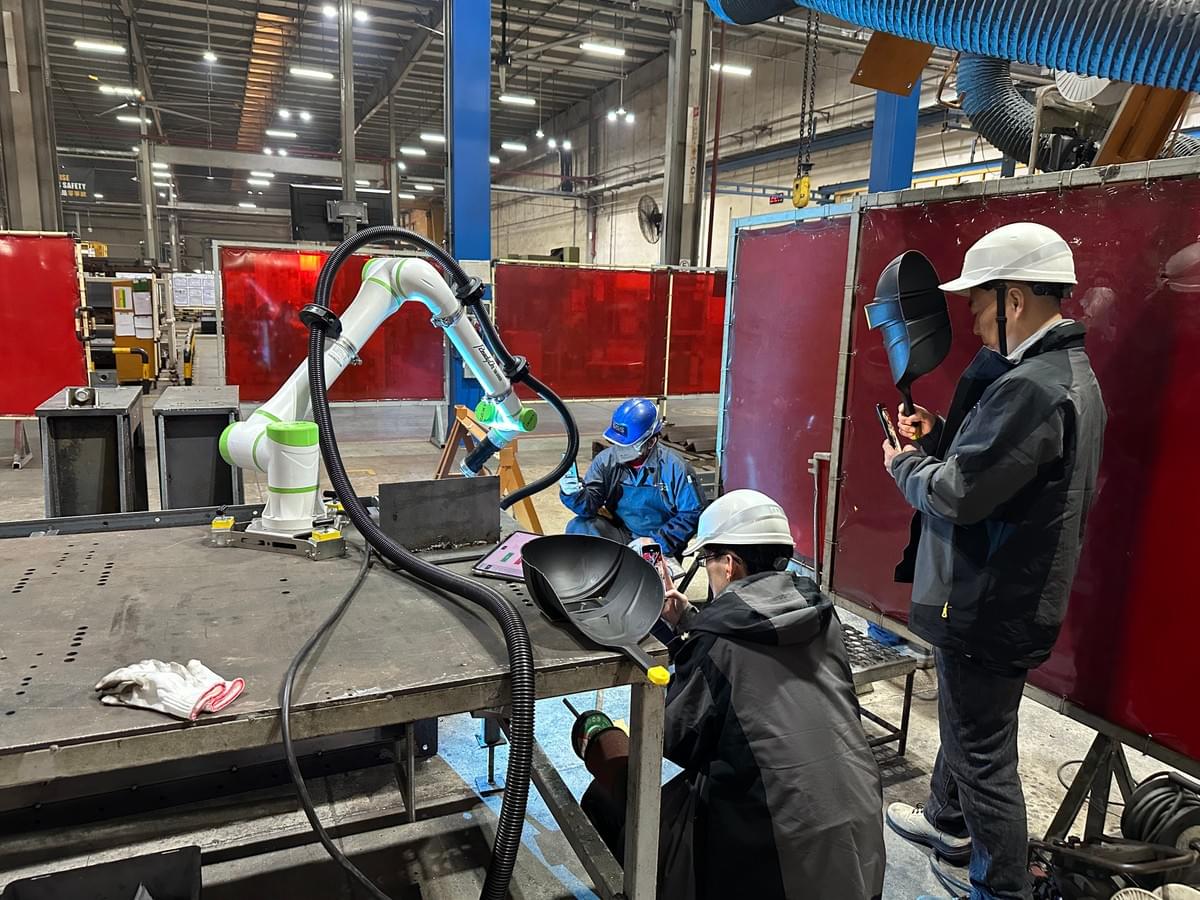

ReadyOn Cobot Welding Complete Multi-Workpiece Welding Verification

Makes Welding Easier!

——2025/11/30

ReadyOn cobot welding were invited to Suzhou Jiesai Machinery Co., Ltd. to conduct on-site welding operations on multiple workpieces of different specifications. This welding operation addressed the complex welding needs of a real-world production scenario, successfully completing welding operations on seven different types of workpieces. The overall results were significant, with many workpieces achieving high-standard completion.

During the welding process, the ReadyOn cobot performed exceptionally well. For workpieces one through four, the robot achieved 100% high-standard completion thanks to precise trajectory control and stable welding output. The welds were uniform, aesthetically pleasing, and fully met production process requirements, earning high praise from the customer. For the more complex workpiece five, both technical teams engaged in in-depth discussions on process optimization, identifying an improvement plan involving adding arc-shaped fixed points and optimizing the welding trajectory. This optimization work is currently underway, and progress will be reported promptly.

For workpieces six and seven, due to special spatial layout issues, the overall completion rate cannot be fully determined at this time. However, in welding sections not subject to spatial constraints, the robot maintained efficient and stable output, achieving the expected completion standard. On-site technicians stated that the space issue provided important insights for subsequent product adaptation and optimization, leading to targeted improvements to the solution.

The successful completion of this on-site welding demonstration demonstrates ReadyOn's continued focus on customer needs and its ongoing refinement of product technology and solutions.

Contact Us

0086 510 8580 8562

ieff.huang@nodha.com

wynne@nodha.com

eileen@nodha.com

Location

12nd Building, No.9 Xingyang Road, Binhu Distric, Wuxi 214082, JiangSu

Subscribe to Our Newsletter